The sphere of infrastructure is moving at a rate that calls for persistent evolutionary breakthrough in its development. As the world grows and reaches new milestones, it subsequently affects the fitness of infrastructure by rendering it obsolete, requiring a need for nifty, more durable, viable and advanced infrastructure solutions that are paramount to integrating with constantly changing trends. In the world today, solutions that make things easier, cost efficient, productive and viable is the current mandate.

The greatest challenge of infrastructure is its susceptible nature to wear and the future of infrastructure is the elimination of this weakness and developing acute scientific strategies to prolong the life of existing infrastructure and create new ones in a profitable manner that is eco-friendly. Given the fact that most infrastructures are outdoors, underground or in contact with water, infrastructure made of steel is surely subject to wear and corrosion damage during use, ranging from mechanical and chemical related impacts or atmospheric conditions like inadequate ventilation, increase in relative humidity, temperature and other climatic

factors. Dorman long is therefore invested and calls for infrastructure that is intelligently planned to integrate with future trends and a much better display of quality technological advancements and solutions that battle issues associated with infrastructural setbacks.

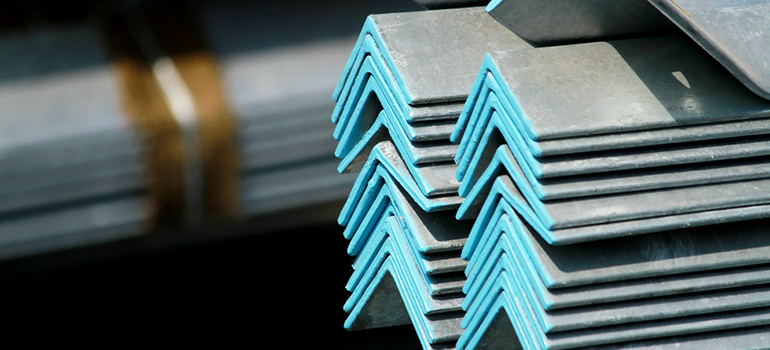

Through our futuristic galvanizing facility, we have deployed engineering assessments that can reshape intelligent infrastructure and have relied on cutting-edge solutions to reinvent infrastructure in its development, manufacturing, utilization, maintenance and corrosion protection stages. The process of galvanizing, a largely tested corrosion protection technique that has proven to be the best coating method during fabrication requires a thorough dipping of steel in molten zinc, an electropositive and somewhat delicate metal at ambient temperature that possesses a blue-silvery form when oxidation is removed and reacts positively to protect other metals when they come in contact with it. This technique deeply has its roots in engineering, since steel protection is an industrial process in the engineering of metallic objects and is guaranteed to occur in the use of metallic objects during engineering activities.

We are highly invested in taking things to the next level and we realise that the fortification of steel against corrosion by techniques of hot – dip galvanizing is predominantly effective because it has a long life expectancy, an outstanding resistance to mechanical damage, subsidizes waste by saving resources and protects the environment due to the fact that hot – dip galvanized steel is largely recyclable. For steel products engineered via industrial metal fabrication, hot dip galvanizing is the choice solution for ensuring coating life and performance is resolute and dependable. When hot dip galvanizing steel, the process requires one dip as opposed to other techniques that might need to be painted or sprayed. Galvanized steel has a long lasting life expectancy and can be recycled, making it eco-friendly with minimal environment costs.

Galvanizing is also highly cost effective, cheaper in relation to other protection techniques. Maintenance is easily deployed as it does not require any overly thought out maintenance plan, only intermittent inspections and wipe downs due to its protracted and reliable life expectancy. As a reputable metal fabrication and engineering company, Dorman long is well versed in the intricacies of hot-dip galvanizing in protecting steel as we use the technique to rationalise our entire fabrication process. Improved technology has refined the process of hot dip galvanization as a better performer in the metal fabrication industry and galvanization has remained highly verified in maintaining the life of steel in harsh atmospheric, mechanical or chemical related conditions for a vast number of products. This attests to the fact that galvanization is the future of infrastructure and has proven itself in the engineering of steel.